PP Hollow Building Formwork Extrusion Line

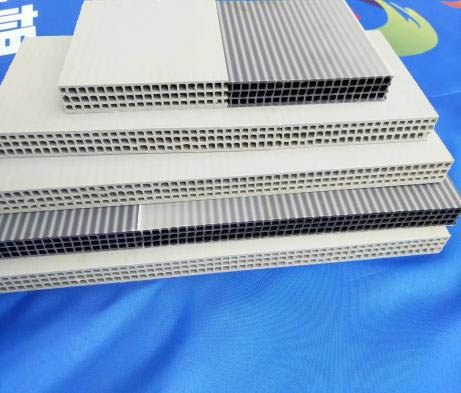

PP Hollow Building Formworkndi mankhwala opulumutsa mphamvu komanso obiriwira oteteza chilengedwe. Ndi chinthu china chatsopano cham'badwo watsopano pambuyo pa matabwa, zitsulo zophatikizika, nsungwi zomata matabwa ndi zitsulo zonse zazikulu. Ikhoza kusintha kwathunthu mawonekedwe achitsulo achitsulo ndi matabwa, ndi kusunga mphamvu, kuteteza chilengedwe ndi mtengo wotsika wa amortization.

Zopindulitsa zisanu ndi zitatu

1. Yosalala komanso yosalala. Fomuyi iyenera kulumikizidwa mwamphamvu komanso moyenera. Pambuyo pobowola, pamwamba ndi kumapeto kwa konkriti zimadutsa zofunikira zaukadaulo zomwe zilipo kale. Palibe chifukwa cha pulasitala yachiwiri, yomwe imapulumutsa ntchito ndi zipangizo.

2. Kuwala komanso kosavuta kuvala. Ndi kulemera kopepuka komanso kusinthasintha kwamphamvu, imatha kuchekedwa, kukonzedwa, kubowola ndi kukhomeredwa, ndipo imatha kupanga geometry iliyonse mwakufuna kukwaniritsa zofunikira pakumanga mawonekedwe osiyanasiyana.

3. Easy demoulding. Konkire sichimamatira pamwamba pa slab ndipo sichifuna kumasula. Ndiosavuta kugwetsa ndikuchotsa phulusa.

4. Wokhazikika komanso wosagwirizana ndi nyengo. Mkulu wamakina mphamvu, palibe kutupa, akulimbana, mapindikidwe, kukula khola, kukana alkali, odana ndi dzimbiri, retardant lawi ndi madzi, makoswe ndi tizilombo othamangitsa pansi kutentha kwa -20 ℃ mpaka + 60 ℃.

5. Zothandizira kukonza. Mafomuwa samamwa madzi ndipo safuna kukonza mwapadera kapena kusungirako.

6. Kusinthasintha kwakukulu. Mtundu, mawonekedwe ndi mawonekedwe akhoza kusinthidwa malinga ndi zofunikira za zomangamanga.

7. Chepetsani ndalama. Nthawi zobwereketsa zimakhala zambiri, mawonekedwe a ndege ndi osachepera nthawi 30, ndipo mawonekedwe amtengowo amakhala osachepera 40, ndi mtengo wotsika.

8. Kupulumutsa mphamvu ndi kuteteza chilengedwe. Zida zonse zotsala ndi zinyalala zitha kubwezeretsedwanso.

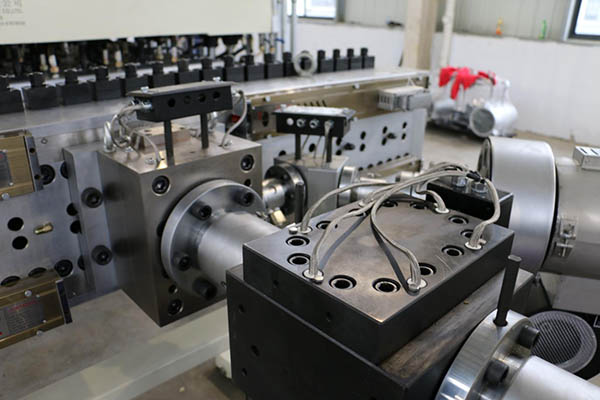

JWELL inapanga PP nkhungu imodzi yopangira template yomanganso mzere wopangira 915mm, womwe sungathe kukwaniritsa zofuna za mphamvu zambiri komanso mphamvu zochepa.

Makhalidwe

1. Njira zitatu zopangira coextrusion

2. Wogawa magawo atatu osanjikiza

3. Multilayer lattice nkhungu

4. Gulu la mitundu itatu

5. Talakitala yophatikiza

6. Makina odulira okhazikika okhazikika

Main luso specifications

|

Chitsanzo |

Zakuthupi |

Extruder specifications |

Kukula kwazinthu(mm) |

makulidwe (mm) |

Kuthekera (kg/h) |

|

JWS130(80)-1320 |

PP zosinthidwa zinthu |

JWS130/35, JWS80/35 |

915/1220 |

12-14/15-17 |

450-500 |

|

JWS150(80)-2000 |

PP zosinthidwa zinthu |

JWS150/35, JWS80/35 |

915*2 |

12-14/15-17 |

550-600 |

|

CJWH85(80/52)-2000 |

PP zosinthidwa zinthu |

CJWH85, CJWH52/JWS80 |

915*2 |

12-14/15-17 |

600-700 |

Zindikirani: Zosinthazi zitha kusintha popanda chidziwitso.

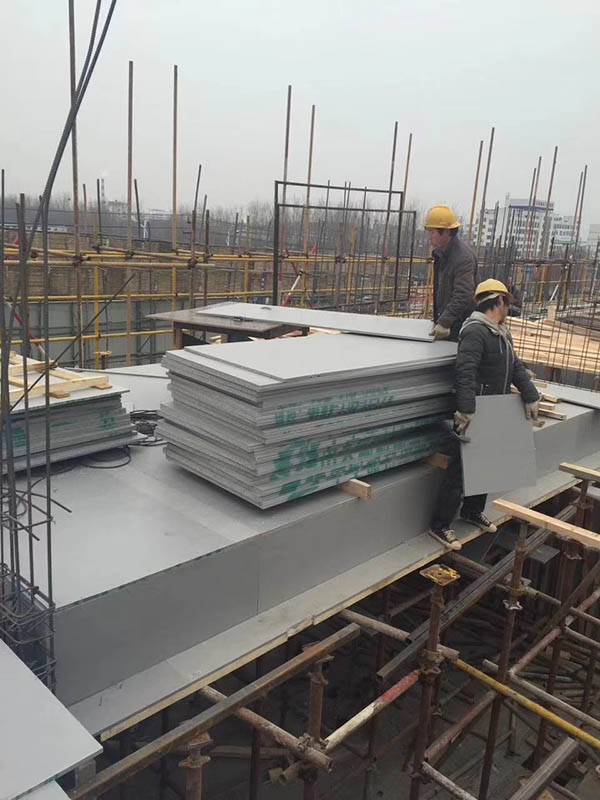

Chiwonetsero chazithunzi

Malo omanga