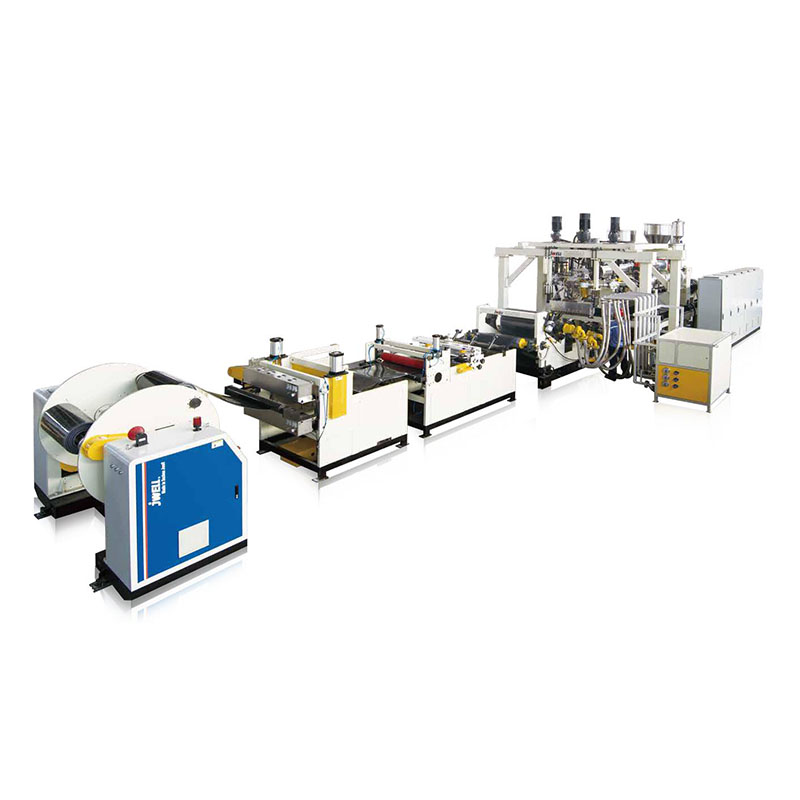

PP ndi Calcium Powder Environmental Protection Sheet Extrusion Line

PP+CaCo3 mwachilengedwe-wochezeka pepala extrusion mzere

Idapangidwa ndi kampani ya Jwell imagwiritsa ntchito ma extruder atatu kapena 4 zigawo co-extrusion. Mzerewu umagwiritsa ntchito chipangizo chaposachedwa cha Jwell chopangidwa ndi PP+CaCo3 chotulutsa mpweya ndi chipangizo chowongolera makompyuta cha PLC komanso chida chodziwira makulidwe ake kuti makinawo athe kukulitsa kuchuluka kwa CaCo3 pakupanga mapepala kuti achepetse mtengo wa pepala ndi pepala lopangidwa limatha. kupeza katundu wabwino thupi ndi zina processing luso. Ndi makina apamwamba kwambiri a mapepala ku China.

Main luso specifications

|

Chitsanzo |

JW-120/100/45-1500 |

|

Kukula Kwazinthu |

1320 mm |

|

Zamgulu makulidwe |

0.3 mm |

|

Layer kapangidwe |

A/B/C/A |

|

Mphamvu |

800kg/h |

Zindikirani: Zosinthazi zitha kusintha popanda chidziwitso.

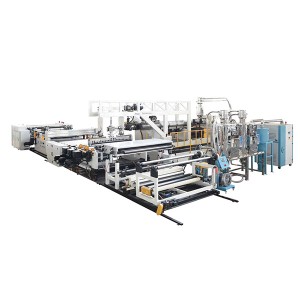

Kuwonetsa zinthu zomalizidwa

Mapangidwe a pulasitiki extrusion makina

Makina akuluakulu a makina opangira pulasitiki ndi extruder, yomwe imapangidwa ndi dongosolo la extrusion, dongosolo lopatsirana ndi kutentha ndi kuzizira.

Extrusion system

Dongosolo la extrusion limaphatikizapo Extruder, Kudyetsa dongosolo, Kusintha Screen, Pampu ya mita, T-die. Pulasitiki ndi plasticized mu yunifolomu kusungunula kudzera dongosolo extrusion, ndipo mosalekeza extruded ndi wononga pansi pa kupsyinjika anakhazikitsa ndondomekoyi.

Screw ndi Barrel: Ndilo gawo lofunikira kwambiri la extruder. Izo mwachindunji zokhudzana ndi ntchito osiyanasiyana ndi zokolola za extruder. Zimapangidwa ndi mphamvu yamphamvu kwambiri komanso zitsulo zosagwirizana ndi dzimbiri. Mgolowu umagwirizana ndi wononga kuti ukwaniritse kuphwanya, kufewetsa, kusungunula, plasticizing, kutuluka ndi kuphatikizika kwa pulasitiki, ndipo mosalekeza ndi mofanana amatumiza mphira ku dongosolo loumba.

Dongosolo la chakudya: ntchito yake ndi wogawana kunyamula mitundu yosiyanasiyana ya mapulasitiki kwa hopper wa extruder.

Kusintha skrini: Ntchito yake ndikuchotsa zonyansa zamitundu yonse mupulasitiki

Pampu ya mita:Kukonzekeretsa mpope kutsogolo kwa extruder, kuyang'ana kuthamanga pamaso pa mpope ndi kulamulira liwiro la extrusion, amene akhoza kuchepetsa pulsation ndi kusasamba zakuthupi kudya ndi kuonetsetsa kuti polima ndi bwino extruded ndi mosalekeza kuperekedwa kwa mutu kufa. Chigoba cha pampu chimatenga zitsulo zamtengo wapatali za alloy ndi

giya imagwiritsa ntchito chitsulo chozimitsidwa cha chrome kapena zida zina zachitsulo zapamwamba zomwe zimatsimikizira kuyendetsa bwino komanso kutayikira.

T-die: Ntchito ya T-die ndikusinthira kusungunuka kwa pulasitiki komwe kumazungulira kusuntha kofananira komanso kofananira, komwe kumayambitsidwa molingana komanso bwino.

Njira yotumizira

Ntchito yoyendetsa galimoto ndikuyendetsa wononga ndikupereka torque ndi liwiro lofunika ndi screw mu ndondomeko ya extrusion. Nthawi zambiri imakhala ndi mota, chochepetsera komanso chonyamula.

Kutentha ndi kuziziritsa chipangizo

Kutentha ndi kuziziritsa ndi zinthu zofunika kuti pulasitiki extrusion ndondomeko kuchitika.

1. Extruder nthawi zambiri imagwiritsa ntchito kutentha kwamagetsi, komwe kumagawanika kukana kutentha ndi kutentha kwa induction. Kutentha pepala amaikidwa mu thupi, khosi ndi mutu. Chipangizo chotenthetsera chimatenthetsa pulasitiki mu silinda kunja kuti chiwonjezeke kutentha kuti chifike kutentha komwe kumafunikira pakugwira ntchito.

2. Chipangizo chozizira cha extruder chimayikidwa kuti chiwonetsetse kuti pulasitiki ili mu kutentha komwe kumafunika ndi ndondomekoyi. Makamaka, ndikupatula kutentha kopitilira muyeso komwe kumabwera chifukwa cha kumeta ubweya wobwera chifukwa chozungulira, kuti kutentha kusakhale kokwera kwambiri kupangitsa pulasitiki kuwola, kuyaka, kapena mawonekedwe ovuta. Kuziziritsa kwa migolo kumagawidwa m'mitundu iwiri: kuziziritsa kwamadzi ndi kuziziritsa mpweya. Nthawi zambiri, ma extruder ang'onoang'ono ndi apakatikati ndi oyenera kuziziritsa mpweya, ndipo zazikuluzikulu zimakhala zoziziritsidwa ndi madzi kapena kuphatikiza mitundu iwiri ya kuziziritsa.